Position:Dynamic news > Industry News

Position:Dynamic news > Industry News Industry News

Industry NewsGuided by national strategic needs, the company has mastered key core technologies such as the 0.12mm ultra-thin electronic touch glass, 30-micron flexible foldable glass, and float glass 8.5-generation TFT-LCD glass substrates. The self-developed float glass micro-defect control technology and equipment have contributed to the rapid development of the automotive industry. The company has also broken through the core technology barriers of ultra-white high-transparency photovoltaic glass, supporting the iterative upgrade of China's photovoltaic industry. It has successfully completed the construction of the world’s thinnest 0.12mm ultra-thin touch glass production line and the country's first float 8.5-generation TFT-LCD glass production line, ensuring the security of China’s trillion-dollar display industry supply chain.

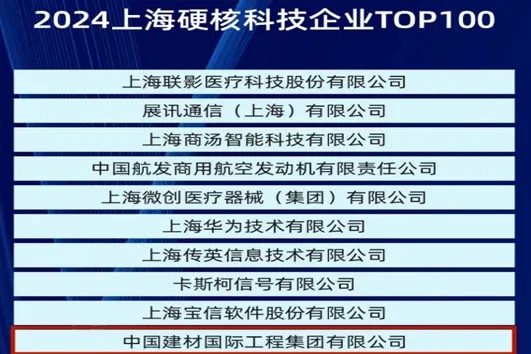

As an "advanced enterprise implementing the 'going global' strategy in Shanghai" and actively responding to the "the Belt and Road" initiative, it has s exported over 60 glass and related engineering projects in more than 20 countries and regions worldwide and has established partnerships with leading global glass manufacturers such as Guardian in the United States and KCC in South Korea. Its share of the global high-end glass engineering market has remained steady at over 65%, promoting the global presence of China technology, China standards, China manufacturing, and China brands. For seven consecutive years, the company has been ranked among the "Top 150 Global Engineering Design Firms" and the "Top 225 International Engineering Design Firms.".

Adhere to the guidance social governance model of Party Leadership and practice the "responsibility of central enterprises". The iterative upgrade of the Party Leadership brand "1,248 Party Leadership System" has won the 1st prize for excellent achievements in China's enterprise reform and development. Received honors such as National Civilized Unit, National Advanced Grassroots Party Organization, National May Day Labor Medal, National Youth Civilization Award,. For eight consecutive years, it has been awarded the titles of "Top 100 Enterprises in Shanghai" and "Top 100 Enterprises in Shanghai's Service Industry". It has also been recognized as a leading enterprise in the Shanghai General Integration and General Contracting Chain and a cultivated enterprise in the Shanghai Industry and Education Chain, contributing to the high-quality development of the local area. Adhere to the principles of "poverty alleviation through science and technology, poverty alleviation through industry", and establish a production line for medicinal neutral borosilicate glass tubes in Wei County, Hebei Province, to safeguard the lives, health, and safety of the people; Building an intelligent glass greenhouse in Xiaogang Village, Anhui Province, to demonstrate the transformation of rural revitalization; Sending village cadres to take root in the front line in places such as Zhaotong in Yunnan and Shitai in Anhui demonstrates the responsibility of central enterprises.